We have a production workshop, which spans more than 8,000 square meters, as well as over 80 sets of production equipment. The production capacity of SUYU is 12,000 tons of bolts and spikes each year, more than 10 million pieces of clips, and a heat treatment capacity of 8,000 tons.

SUYU also has the in-house capability to design and process molds, which can ensure the quality of molds and also reduce production costs in a fast and efficient manner.

In addition, we have 27 vertical pressing machines available in capacities ranging from 40 tons to 250 tons.

These machines can effectively accomplish the manufacture of threaded products. Then we use the thread making machine to guarantee the quality, and we also employ highly-experienced packaging operators who can ensure the clear identification and traceability of all railway products.

The production workshop spans more than 8,000 square meters. It is outfitted with over 80 sets of production equipment, including 27 sets of vertical pressing machines in capacities ranging from 40 tons to 250 tons, 8 sets of threading machines and 4 net-belt type heat treatment production lines. Backed by the efficient production devices, the annual production capacity of bolt spike is 12,000 tons, annual capacity of spring bar is more than 10 million pieces, and the heat treatment capacity is 8,000 tons.

Raw materials processing workshop

Raw materials processing workshop Profiling shop

Profiling shop

Our raw materials are supplied by large steel manufacturers, such as SHAGANG Group and SHOUGANG Group. The raw materials are classified into different categories and are strictly tested according to our company’s quality control procedures. The stable quality of the raw materials ensures the quality of our products.

Steel pipes

Steel pipes

The 3 automatic feeding cutting machines achieve the output of 60,000 parts. Designed and manufactured by our own technicians, the automatic feeding device effectively controls the workpiece size of the broken material to 0.5mm, thus guaranteeing the accuracy of broken materials.

Cutting of raw materials

Cutting of raw materials Steel

Steel

We are equipped with 10 sets of semi-automatic chamfering, turning and pointing machines with the output of 6-8 million parts per shift. The semi-automatic turning and pointing machine can control the turning and pointing angle and length to realize effective control of the quality of the turning process.

Chamfering

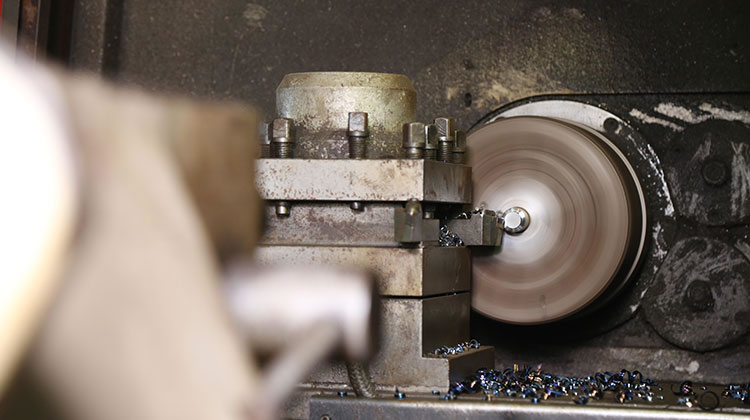

Chamfering Close view of chamfering

Close view of chamfering

We have 7 sets processing equipment and 2 sets of CNC lathes. The molds are independently processed by our company to ensure high quality of the mold and saves production costs.

Workpiece polishing

Workpiece polishing CNC lathe operation

CNC lathe operation Close view of CNC lathe processing

Close view of CNC lathe processing

Forging machines

Forging machines Forging

Forging

SUYU’s production workshop is furnished with 18 forging presses and 9 sets of automatic infrared-control 160-ton punching machines. The machines are easy to operate and adjust. It features high production efficiency and protect workers from injury caused by incorrect operation during the operation of machines.

Cutting edge

Cutting edge

Thread pressing

Thread pressing Medium frequency heating device for thread pressing

Medium frequency heating device for thread pressing

There are 10 threading machines in our production workshop and 5 thread rolling machines are modified for infrared control. The automatic temperature control medium frequency heating device is equipped to ensure the length of products.

Thread rolling

Thread rolling

The screw spikes are finished with wax and automatic temperature control ensures the quality of wax finishing.

Semi-finished products to be tested

Semi-finished products to be tested Screw spikes

Screw spikes Spikes

Spikes Wax finishing

Wax finishing

We strictly control the quality of the fasteners before packaging to remove the unqualified products. The packaging workers and the products are identified with specified numbers, so the packaging quality and quantity are clear to trace.

Packaging and sorting

Packaging and sorting Top view of packaging and sorting

Top view of packaging and sorting

Finished products warehouse

Finished products warehouse Railway spring bar production shop ready for production

Railway spring bar production shop ready for production

Shanghai SUYU Railway Fastener Company Ltd.

Add.: Room 1737, 15th Building, No.201, Jinxiang Road, Pudong New Area, Shanghai, China

E-mail:suyu@suyurail.com

Contact Person: Linda Yuan